Precision Void Fill Solutions in West Michigan

The Hidden Problems of Unfilled Voids

Gaps, voids, and cavities in walls, floors, and around piping can lead to energy loss, pest intrusion, moisture problems, and even structural settling. Don’t let hidden spaces compromise your building’s performance or safety.

Complete Air &

Moisture Seal

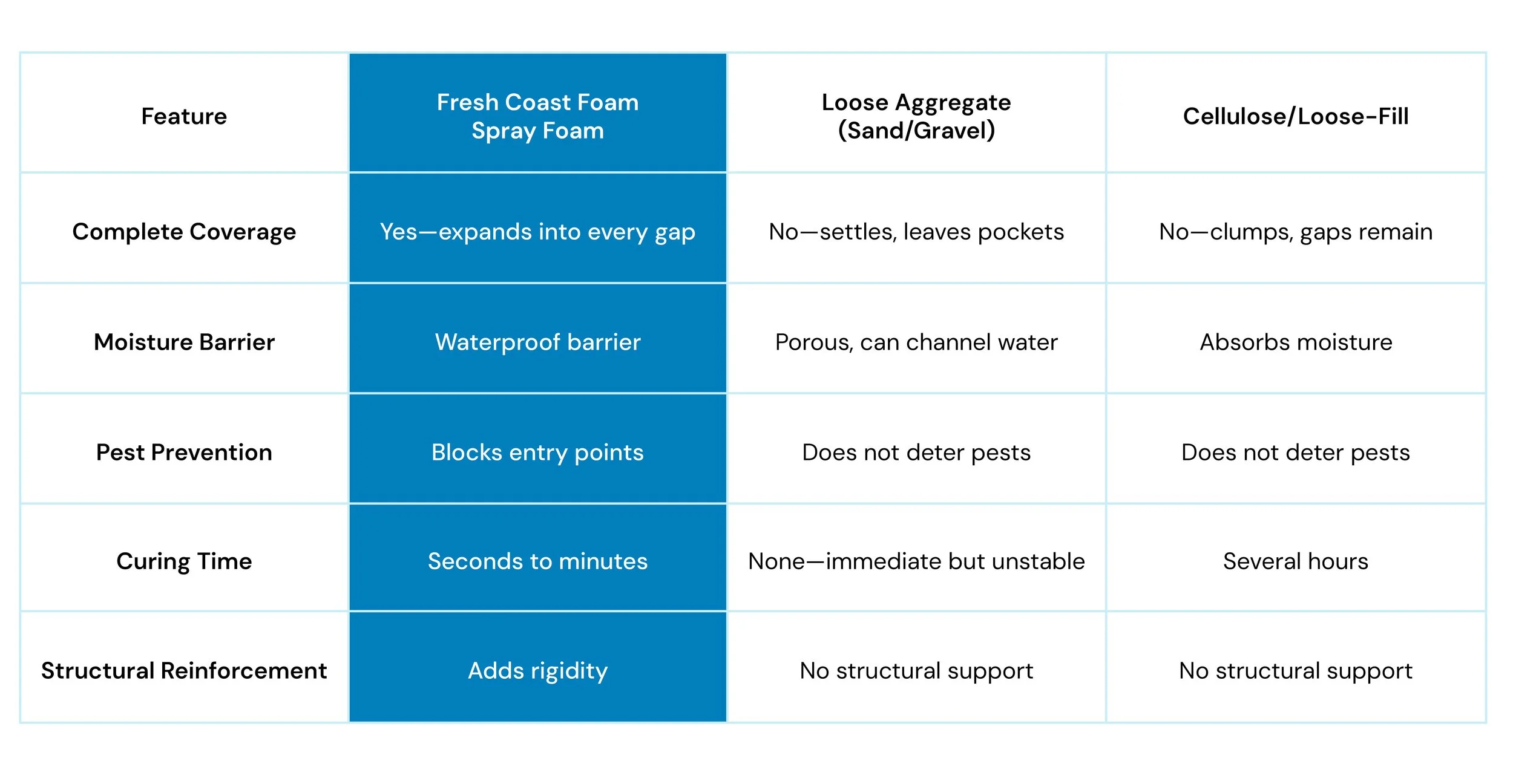

Why Choose Spray Foam for Void Fill

Closed-cell spray foam expands to fill every nook and cranny, creating an airtight, waterproof barrier that rigidly bonds to surfaces.

Pest-Proof

Barrier

Once cured, spray foam blocks entry points and has no voids for pests to nest or hide—unlike traditional backfill or loose materials.

Rapid Application & Curing

Our high-pressure equipment sprays foam into deep or tight cavities, curing in seconds to restore insulation value and stability.

Structural

Support

Closed-cell foam adds strength to backfill areas under slabs, behind foundation walls, and between block cores—preventing future settling.

Our Void Fill Process

Site Inspection & Mapping

We identify all void locations—around pipes, behind walls, under slabs—and assess access points.Small Access Drills

Precision-drilled ports (⅜"–½") allow targeted foam injection, minimizing wall or slab disruption.High-Pressure Foam Injection

Closed-cell polyurethane foam expands uniformly, filling voids, sealing gaps, and bonding to adjacent surfaces.Port Sealing & Cleanup

We cap or patch drill holes flush, remove any debris, and leave your site clean and ready for immediate use.

Why Multiple Insulation Types Matter

Frequently Asked Questions

-

Yes. We integrate seamlessly into your project timeline and meet all on-site requirements, including safety orientations and access protocols.

-

Absolutely. Fresh Coast Foam has the manpower, equipment, and project management expertise to tackle portfolios, campuses, and multi-phase developments.

-

Our team is trained to ASTM and ICC guidelines for spray foam, and we install materials that meet ENERGY STAR®, LEED®, and local code requirements.

-

We use containment methods, negative-pressure ventilation, and proper curing times to keep your workspace safe and operational.

-

We offer a 10-year workmanship warranty plus manufacturer warranties on all materials—so your investment is protected. Contact us for a personalized quote.